FIBC

Quality & Hygiene

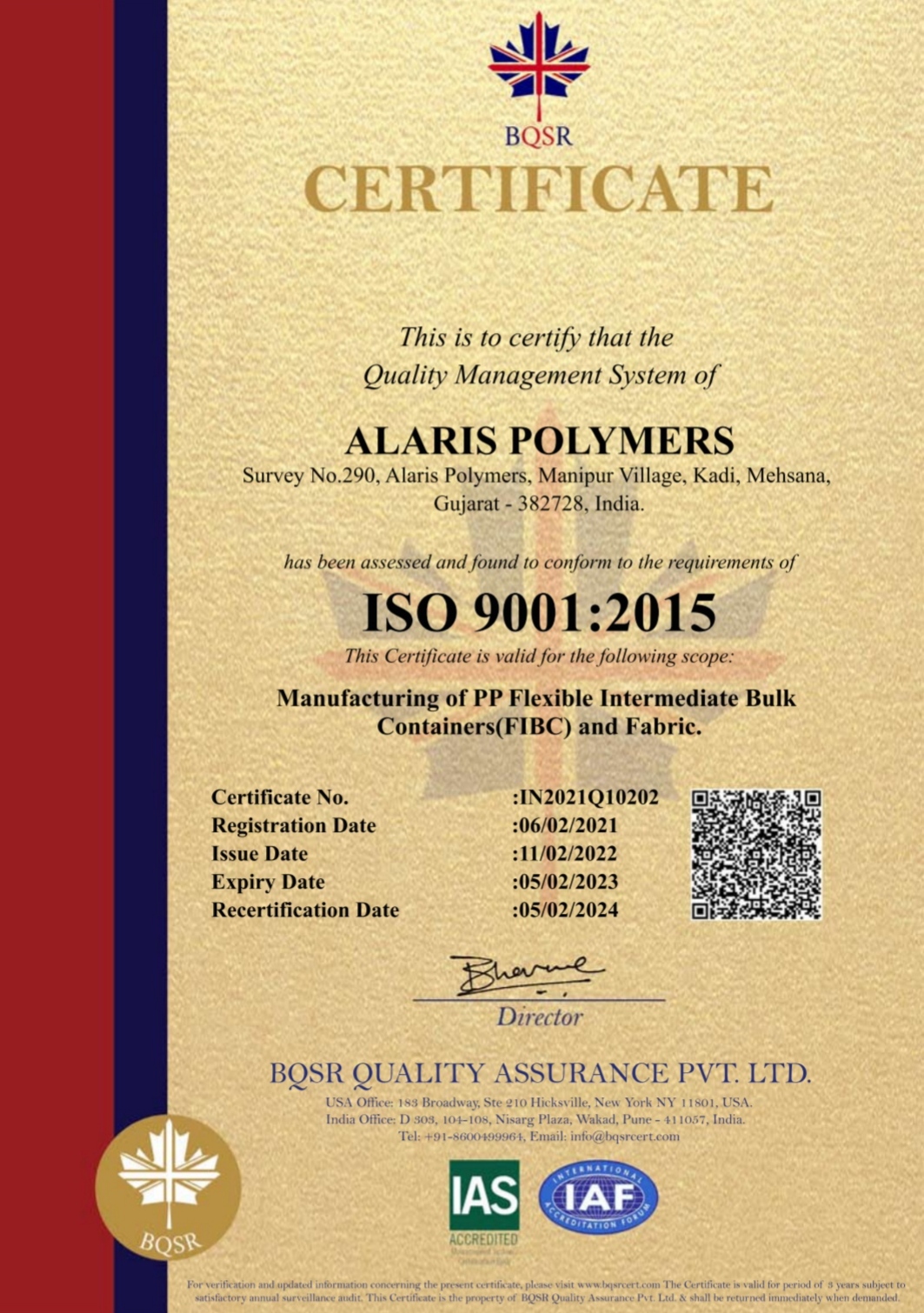

Quality Assurance:

Quality is the most prime dimension of any operation management. Ever since inception, our focus on the right quantity served at the right time while maintaining the quality of the product has enabled us to become the leading FIBC big bag manufacturer.

To serve the optimum quality product, we have implemented an effective quality control program in which we have defined the standard of the quality for each product. Our quality assurance team conduct the lasting quality assurance program to be ensured that everything from raw materials to inspection procedure is of the highest quality.

Hygiene :

As a top-notch FIBC big bag manufacturer, we follow the policy that the offered product must comply with the highest standards and protocols. We have developed hygienic and environment-friendly systems that avoid contamination and dirt. During the manufacturing process, all workers wear gloves, face masks, headgear and shoes to maintain very high level of hygiene.

To make food grade FIBCs and pharma grade FIBC dust free, germs free and pollutants free, all conveyors at Alaris Polymers are made of food grade rubberized material. In addition, we have installed adequate flying insect traps to trap any insects inside the factory.